To make an unbiased comparison and provide a weighed and grounded conclusion, it is necessary to know what is a miter saw good for and what are the table saw major purposes, how these tools compare, what is the main difference between them, and how to utilize each of them properly.

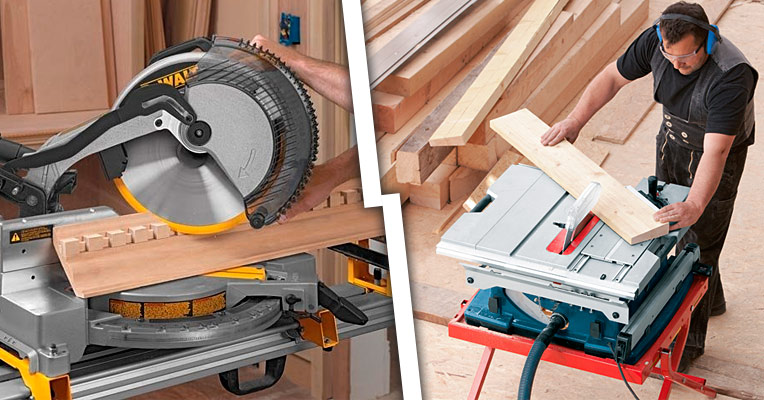

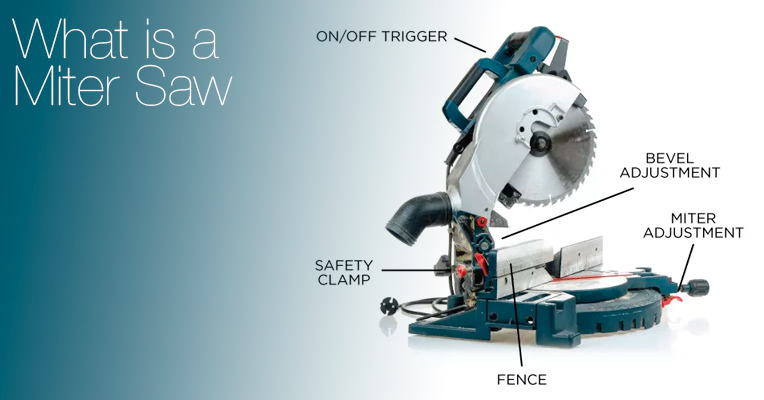

A miter saw is a powered cutting tool which normally requires some kind of a countertop or bench top to be operated. The tool consists of a circular saw head that is installed on a kind of stand over a round cutting table with a fence. The blade rotates at different speeds and can be moved downwards and upwards to make cuts. As the name suggests, this saw is good for making miters as well as other types of angled and orthogonal cuts between 45 and 90 degrees. Despite a great variety of models described in miter saw reviews, they all fall into two major types.

A standard saw is a basic type that goes straight down and cuts only vertically. Yet, commonly, it features a guide allowing you to cut at an angle up to 60 degrees.

A compound miter saw comes fitted with a cutting head that rotates on a pivot enabling you to tilt the blade sideways for bevelling. This type is called compound since it can be set to make a miter cut and a sloped bevel cut at the same time. In addition to a compound miter saw, you can find a sliding compound miter saw with the blade sliding in or out for working with larger wood pieces. Miter saws are great for framing and cutting moldings. They deliver smooth cutting results not only on wood but also on plastic, aluminum or concrete.

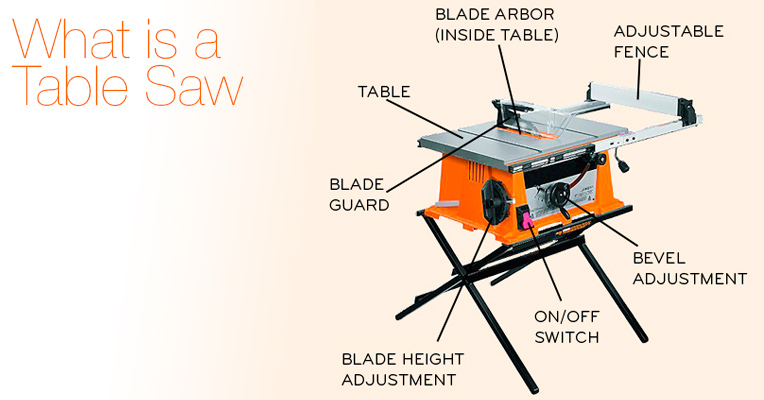

Similar to a miter saw, the main part of a table saw is a circular saw cutting blade that is installed in a stand or table and powered by an electric motor. While with a miter saw you have to move the cutter using a handle, in the case of a table saw the blade rotates in a fixed position meaning you will have to move a workpiece manually to make the necessary cut. The blade height is adjustable to vary the cutting depth. Besides, the blade can be angled to make miter cuts.

Table saws also fall into two basic types: portable and stationary machines. If you, like many other DIYers, are wondering which of these two is considered the best table saw, we're likely to disappoint you as the answer to this question isn't definite and will depend on what exactly you need to do.

Portable units are further subdivided into compact and lightweight models for home use and somewhat larger and more powerful machines with wheeled frames and folding stands for on-demand jobsite applications. Stationary units are usually pretty bulky and heavy. They are not meant for often transportation and are specifically designed for professional use and large heavy-duty projects. Table saws are suitable for a variety of cutting jobs. You can do cross cuts and miter cuts, bevels and rips, rabbets and dadoes or even shape the woodstock edges if necessary. If you need to lay wooden flooring or build up a veranda or terrace, a table saw will become your best-ever helper.

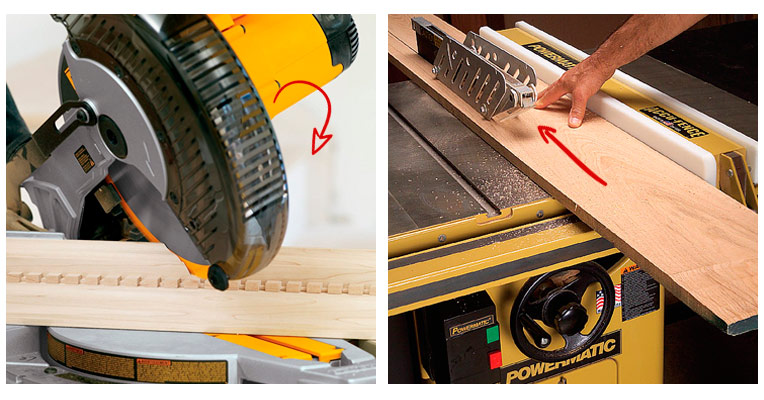

Though both tools are widely applied in woodworking, they greatly differ in their design and principle of operation. Using a pretty much similar cutting head, they apply different cutting principles, which define their scope of application and cutting jobs each of the tools is good for. Providing an operator an ability to control the movement of the blade, a miter saw allows for more precision and control over the cutting process, which is essential when it comes to delicate and more elaborate small-scale woodworking projects as well as fine cutting jobs where the ultimate cutting accuracy is needed.

Cross cuts and angled cuts on the boards from 6 to maximum 12 inches wide are where a miter saw really shines. With a table saw, you will have to move the material along the blade that allows making both cross cuts and rips. Though table saws might be somewhat inferior to miter saws in cutting precision, they definitely provide more flexibility and versatility for the jobs at hand. Besides, thanks to a supportive table, table saws allow processing larger workpieces, including plywood sheets, wood panels, and long boards.

It’s common knowledge that in order to get the most out of your tool, you should not only have a certain level of skill but also use the right tool and do it properly. Below we've summed up what tasks can be done with a miter saw and what rules it is best to follow to enhance the tool performance.

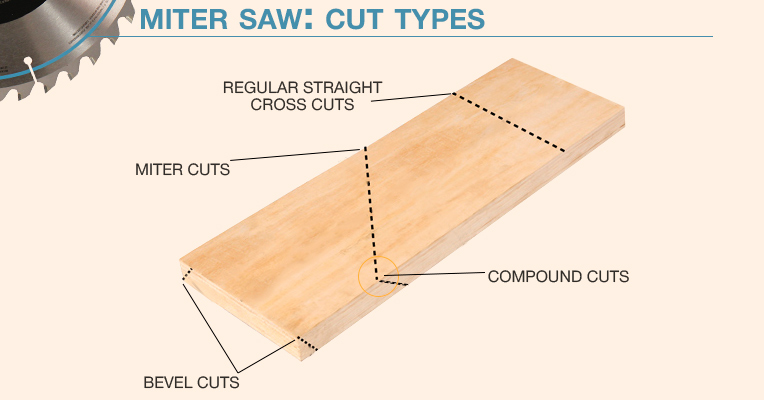

A miter saw is normally used for 4 most widely used types of cuts:

Regular straight cross cuts. When you need to cut a board in half, a miter saw will do it quickly with a minimum of effort. Simply mark the cutting line, align the blade and make the cut. Cutting boards for flooring or any type of wood facing jobs will be a breeze.

Miter cuts made across the board width. To make miters you will need to turn the saw to one side or the other. The majority of miter saw models will cut from 45 to 90 degrees. This type of cuts is widely used in a variety of woodworking projects that have angles, from furniture making to framing, and all kinds of trimming works for remodelling and refinishing projects.

Bevel cuts made into the board thickness. For bevel cuts, you will have to adjust the blade angle. Bevel cuts are widely used in carpentry and crafting to create more aesthetic and solid joints.

Compound cuts that combine both miters and bevel cuts. In order to make these cuts, you will not only need to turn the blade sideways but will also need to set it at a certain angle. Compound cuts are used for crown molding and complex angles.

Miter saws are initially designed to deliver quality clean cuts and most models can do that flawlessly even under extensive daily use. However, there are some tips on how you can further maximize your tool to achieve even better results for different tasks.

- Upgrade your blade. A 24 to 40-tooth blade which usually comes included in the package is mostly suitable for cutting softer woods. However, if you need to make a clean cut in a hardwood stock, it is recommended that you take an 80 to 100-tooth blade with a lower degree hook angle.

- Stop before you lift the cutter. Once you’ve made a cut, let the blade stop completely before you lift it. Thus, you’ll get a cleaner cut since a spinning blade might score the workpiece end.

- To prevent the blade flex when cutting through hardwoods or solid materials, cut in two steps. Make the first cut about a half of your cut line and then finish it at a second pass.

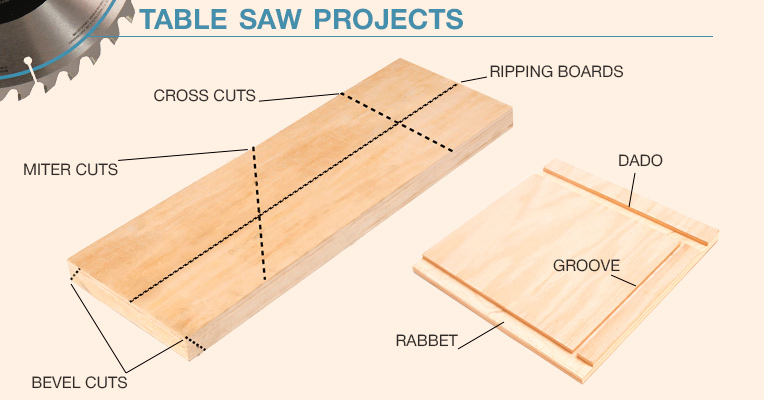

What is a table saw used for? Tables saws stand out for their functional versatility. Whether you go for a lighter domestic model or for a more heavy-duty one, you’ll be able to accomplish a variety of tasks, from simple outing cutting jobs to more tricky cuts.

Ripping boards. Cutting the board lengthwise is the most common type of task you can do with a table saw. Before you start to cut, remember to adjust the fence width and set the blade guard accordingly. To prevent kickbacks, it is recommended that you adjust the blade height so that it was about 0.25 inches over the workpiece thickness.

Cross cuts and miter cuts. Just like a miter saw specifically designed for angled cuts, a table saw also allows making cross cuts and miter cuts which are widely used in joinery, cabinetry, and flooring. You will just need to use a special miter gauge and a drafting triangle to make precise and clean angled cuts. Hence, making trim with a table saw is a breeze.

More sophisticated cuts. By getting some additional accessories, you can further expand the functionality of your table saw. Thus, a set of special dado blades will let you make dado cuts and rabbets. Meanwhile, by using a jointer jig, you’ll be able to straighten curved or crooked boards or even make box joints.

Well, which one of two tools is better? Actually, there is no single answer to this question. The right answer would be “it depends”. It depends on the type of project you have at hand. One thing is for sure, a miter saw is not suitable for rip cuts and it does not provide the versatility of table saws necessary for making more tricky and sophisticated cuts. On the other hand, a miter saw provides more accuracy and precision that are needed to perform fine cutting tasks.

In conclusion, we can suggest you consider a miter saw if you need a tool for occasional use and minor home applications, while if you're engaged in woodworking seriously and perform different kinds of cuts on a regular basis, we'd recommend that you see into the table saw that offers more flexibility.